Metal scrap shredder

Nowadays the largest industries are tasked with dealing with how they can manage their accumulated metal waste in the best way. An ideal solution for all-size metal scrap reduction needs is a shredder that offers reliable and effective shredding performance. Increased ease in handling, saving space, and requiring less manpower are the most important benefits of metal scrap shredder.

Shredders controlled by a PLC system, make everything small and compact their volume by cutting, shearing, and tearing the materials to meet the demands of the subsequent processes, especially recycling activities. Metal scraps are usually sorted and then shredded into homogenous pieces of metal products.

Metal scrap shredder structure

This machine is mainly composed of:

- Hydraulic or electric motor

- Reducing gearbox

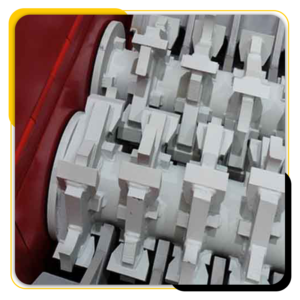

- Main shaft attached with blades or hammers

- Fixed blades

Shredder motor

The shredder feeding system is either a hydraulic or electric motor. Depending on the type of operation, we need to consider several factors about the motor including size, flexibility, and the noise it produces during operation. Metal scrap motor works in double directions so the shafts will reverse automatically when encountering extremely hard objects.

Gearbox

The gearbox helps with controlling the speed of the shredder motor. Reducing speed causes high torque, low noise, low dust, etc.

Shredder shaft

Metal scrap shredders are divided into single or multi-shaft (two or four shafts) shredders. Hammers or blades are installed equally along the length of the main shafts and are called moving knives. They play a key role in the processing cycle of the machine. The material of blades is generally alloy steel containing manganese. Depending on the material of the blades, the output and shredding performance of the machine will change.

Based on experiments accomplished by Xianyan and coworkers in 2016, by increasing cutouts on the hammerhead of the shredder, we can improve shredding efficiency by 20% and lengthen the useful life of the hammer by 15%.

Fixed blades

Fixed blades are cutters that are equally installed and arranged in a row by the side of the rotor.

Working principle of scrap metal shredder

A metal scrap shredder is driven by hydraulic or electric motors and is controlled by a PLC system. Metal scraps fall into the shredder entrance and under different kinds of forces including extrusion, tearing, shearing and impact, they deform and break into smaller fragments until they become small enough to leave the shredder cavity. Through the reducing gearbox, the motor’s high speed is decreased so the torque increases and energy consumption will decrease.

The material of the scrap also affects energy efficiency. Based on the studies done by X Zhou in 2016, we can reduce energy consumption by shredding different materials separately.

Let’s raise your industry to the next level now!

you can benefit from our 3 decades of experience in the design and manufacturing of efficient, productive, and reliable, machines for metal waste management and recycling processes. we are proud to provide any services based on your needs.

keivankaveh uses smart technology in machines and has 100% control over engineering and manufacturing them, so it allows us to guarantee the highest reliability and productivity.

our equipment is built to last even in tough conditions and they come with a one-year guarantee on the entire product.

Please contact us for any questions and requirements by sending an Email to: info@keivankaveh.com or you can call or contact us on WhatsApp at +989353949294. We will respond to you as soon as possible

.jpg)

دیدگاهی ثبت نشده